Introduction

Many hobbyists are surprised to find that, despite being wired correctly and powered with a 12V supply, their NEMA 17 stepper motor setup runs hot, skips steps, or simply doesn’t produce enough torque. One of the most common culprits is the widely used, budget-friendly L298N driver.

If you’ve connected a NEMA 17 to an L298N, seen it “work” on your bench, and then watched it fail under a real-world load, you’re not alone. Why does it behave this way? More importantly, why does this combination continue to appear in so many tutorials and kits?

The truth is that, while the L298 can spin a stepper motor, it was never designed for the demands of modern stepper-driven systems. It lacks critical features such as current control, thermal management, and microstepping support—features on which NEMA 17 motors depend for accurate and reliable motion.

What We’ll Cover in This Technical Breakdown

- What the L298 and NEMA 17 were designed for

- Why they’re fundamentally incompatible

- The hidden performance issues that arise, such as overheating and torque loss

We’ll also debunk common myths still circulating online.

We’ll also cover the best modern alternatives and how to choose the right driver for your motor.

By the end, you’ll understand why the L298 fails with NEMA 17 motors and what to use instead to achieve better, safer, and smoother motion control in your projects.

⚠️ TL;DR — Executive Summary

- The L298N driver is not suitable for NEMA 17 stepper motors in real-world applications.

- It lacks essential features like current control, microstepping, and thermal protection.

This leads to overheating, torque loss, and skipped steps, even when everything is wired correctly.

It only “works” under light or no load and fails quickly when used for 3D printing, CNC, or robotics.

Use A4988, DRV8825, or TMC2209 instead. These drivers support regulated current, smooth motion, and safe operation for NEMA 17 motors.

Understanding the Core Components

To understand why the L298 driver often fails when paired with NEMA 17 stepper motors, it’s important to first understand the two core components involved: the NEMA 17 stepper motor and the L298N driver. This section explains each component in detail to establish a clear technical foundation for the compatibility issues discussed later.

What Is a NEMA 17 Stepper Motor?

The term NEMA 17 refers to a standardized frame size set by the National Electrical Manufacturers Association (NEMA). Specifically, it defines a stepper motor with a faceplate measuring 1.7 x 1.7 inches (43.2 x 43.2 mm). However, while the frame size is consistent, internal electrical specifications, such as coil resistance, voltage, and current ratings, can vary significantly between models from different manufacturers.

Most NEMA 17 stepper motors used in DIY electronics and light industrial automation are hybrid stepper motors with 200 steps per revolution (1.8° per step). These motors operate using bipolar winding configurations, which require precise current control for efficient torque generation and step accuracy.

Typical electrical and mechanical characteristics include:

- Rated current: 1.0 to 2.0 A per phase

- Rated Voltage: Often between 2 V and 4 V, though higher voltage operation is achieved via current regulation rather than voltage supply.

- Holding Torque: Ranges from 30 to 70 N·cm, depending on the build and magnet structure.

- Phase Resistance: Typically between 1 and 2.5 ohms.

It is important to note that stepper motors are current-driven, unlike DC motors, which are voltage-driven. Therefore, operating them efficiently requires a driver that can accurately limit and regulate current.

Common applications of NEMA 17 motors include:

NEMA 17 stepper motors are widely used in applications that require precise position control, including:

- 3D printers: X, Y, and Z axes, as well as the extruder

- CNC machines: Lightweight gantry movement and tool head positioning

- Robotic arms: Articulated joints with moderate torque demands

- Camera sliders and gimbals: Smooth, incremental movement

- DIY automation projects: XY plotters, laser engravers, and pick-and-place mechanisms

For engineers looking to source reliable NEMA 17 stepper motors with detailed datasheets and consistent build quality, StepmoTech offers a wide selection of hybrid stepper models designed for CNC, 3D printing, and precision automation use. Their catalog includes motor variants with different torque ratings, coil resistances, and mounting options, making it easier to match motors to specific driver and application requirements.

These products are popular because they balance compact size, sufficient torque, and affordability. They are the go-to choice for makers and professionals.

How the L298N Dual H-Bridge Driver Works

The L298N, developed in the 1980s, is a dual full H-bridge driver IC originally intended for controlling brushed DC motors and inductive loads. It remains widely used today due to its availability, simplicity, and low cost. However, its design is not optimized for modern stepper motor control.

At its core, the L298 contains two H-bridge circuits, each of which can switch and control the direction of current through a motor coil. Each bridge consists of four bipolar transistors (BJTs) arranged in an H configuration. When configured together, the two bridges can control the two phases of a bipolar stepper motor.

The L298 contains two H-bridge circuits at its core, each of which is capable of switching and controlling the direction of current through a motor coil.

According to the STMicroelectronics L298N datasheet, the IC was originally intended for brushed DC motors and general inductive loads. However, it lacks key features such as current sensing, decay mode control, and microstepping support.

Key characteristics of the L298 chip include:

- Maximum output current: 2 A per channel (but typically derated to ~1 A continuous without heatsinks)

- Supply voltage: 5V logic input and 7V to 46V motor voltage (Vs)

- Voltage drop: around 1.8–2.5 V per leg under load due to BJT saturation

There is no built-in current limiting. It relies entirely on external current management.

The chip is usually mounted on a breakout board, commonly called the L298N module, which integrates:

- Logic inputs (IN1–IN4) for direction control

- Enable pins (ENA and ENB) for pulse width modulation (PWM) speed control

- A 5V regulator for an optional logic voltage supply

- Terminal blocks for motor and power connections

It handles DC motors and stepper motors.

When controlling DC motors, the L298 operates straightforwardly: one H-bridge per motor allows for direction and speed control using logic pins and pulse width modulation (PWM). The chip performs adequately in this application, especially in basic robotics and remote-control vehicles.

However, when controlling bipolar stepper motors, the driver must manage two phases simultaneously by toggling the current in a synchronized pattern to achieve accurate stepping. While the L298N can energize both phases alternately, it lacks critical features such as current sensing, microstepping, and decay mode control for smooth and efficient stepper motor performance.

Without these features, the L298N is limited to full-step or basic half-step modes, which often result in:

- Increased vibration

- Noisy operation

- Poor torque regulation

- Skipped steps at higher speeds

Visual reference: Simplified Block Diagram

+Vs (Motor Supply) |

[ H-Bridge A ]

/ \

IN1 --| |-- OUT1

| L298 Chip |

IN2 --| |-- OUT2

\ /

[ H-Bridge B ]

/ \

IN3 --| |-- OUT3

| |

IN4 --| |-- OUT4

\_____________/

|

GND

This simplified block diagram shows how the L298 controls two motor coils (or one stepper motor). Each H-bridge allows current to flow in either direction through its connected motor coil. However, it’s clear that this design lacks intelligent current regulation, which is a core requirement for reliable stepper motor control.

Key Technical Mismatches Between the L298 and NEMA 17

As discussed in the previous section, NEMA 17 stepper motors are precision actuators driven by current, while the L298 is a legacy H-bridge driver primarily designed for simple DC motor control. While they can be wired together, the L298’s electrical and thermal characteristics make it fundamentally unsuitable for driving NEMA 17 motors under real-world conditions. This section breaks down the core technical mismatches that lead to poor performance, instability, and eventual failure.

Voltage Drop and Power Dissipation in the L298

One of the most significant limitations of the L298 is its high internal voltage drop. Because the chip uses bipolar junction transistors (BJTs) in its output stage instead of more efficient MOSFETs, it introduces a voltage drop of approximately 1.8V to 2.5V per leg, depending on the current draw and supply conditions.

For a bipolar stepper motor like the NEMA 17, which often runs at low voltages (e.g., 3.3 V to 5 V nominal), this drop is critically important. For instance, when powered by a 12V supply, the effective voltage delivered to each coil may decrease to 7V or less after considering dual-leg losses in the H-bridge. This severely limits the motor’s ability to generate full torque, especially at higher speeds, when voltage headroom is essential to overcome back EMF.

In addition to reduced torque, the power lost across the driver (as heat) increases substantially. Each leg dissipates power according to the formula P = I × Vdrop, which can rapidly accumulate under continuous load. For instance, with a current of 1.2 A per phase and a voltage drop of 2 V, each H-bridge channel dissipates 2.4 W as heat, resulting in significant thermal buildup. This inefficiency not only drains power unnecessarily, but it also pushes the chip toward thermal shutdown during longer sessions unless active cooling is used.

Inadequate Current Handling Capabilities

Most NEMA 17 stepper motors require between 1.2 and 2.0 A per phase for optimal performance. While the L298 is rated for 2 A per channel, this is a theoretical absolute maximum and not a sustainable operating condition. In practice, without substantial heatsinking or forced airflow, the L298 can only handle ~1 A continuously before thermal throttling or, in some cases, full driver failure.

Unlike modern stepper drivers, the L298 has no internal current sensing or limiting circuitry. This means that all current control must be handled externally, either with series resistors, which introduce more power loss, or with complex monitoring systems. Neither option is practical for typical hobbyist or embedded projects.

In real-world tests, such as driving a 1.5 A-rated NEMA 17 stepper with the L298 for sustained periods, users frequently observe the following:

- Thermal shutdown after two to three minutes of moderate torque cycling

- Significant heat rise on both the chip and motor casing (>70°C without a heatsink)

- Erratic step behavior under load due to voltage sag and thermal instability

These limitations render the L298 an unreliable choice for tasks requiring consistent torque or extended runtime.

The Absence of Current Control for Microstepping

Modern stepper motor applications increasingly rely on microstepping, in which current is precisely modulated through the motor coils to create finer intermediate steps. This improves motion smoothness, reduces audible noise, and increases positioning accuracy.

Microstepping relies on the driver’s ability to dynamically regulate current—adjusting it in real time according to predefined sine-wave or trapezoidal profiles. This is typically achieved using chopper drivers, such as the A4988, DRV8825, or TMC2209. These drivers include:

- Current feedback loops with internal sense resistors

- Adjustable current limits

- Fast and slow decay modes for coil demagnetization

The L298 lacks such regulation. It outputs a full-on or full-off signal to each coil, which effectively forces the motor into full-step or basic half-step operation. The result is:

- Increased mechanical vibration

- Lower positional resolution

- A higher risk of skipped steps, especially during rapid direction changes or acceleration

Without microstepping, tasks requiring fine motion control, such as 3D printing or CNC milling, suffer from visible artifacts, inconsistent line quality, or mechanical resonance. Often, users mistake these symptoms for motor defects when they actually stem from the driver’s architectural limitations.

Consequences of Using the L298 with NEMA 17

As outlined in the previous section, there are three core technical mismatches between the L298 driver and NEMA 17 stepper motors: significant voltage drop, inadequate current handling, and the absence of current control for microstepping. These limitations aren’t just theoretical; they result in measurable, often severe, performance issues in real-world applications. This section explores these consequences in detail, including overheating, torque loss, and wasted power.

Motor Overheating and Underperformance

One of the most immediate and visible effects of using an L298 driver with a NEMA 17 motor is thermal overload. Since the L298 lacks current regulation, it delivers full voltage pulses to the motor coils regardless of the load or torque demand. This leads to constant full-coil energizing, even when the motor is idle or lightly loaded.

Modern drivers have current control mechanisms that adjust the energy delivered to the coils dynamically, reducing waste and preventing excess heat buildup. Without this control, the NEMA 17 motor can draw more current than necessary, especially at low speeds or during hold states.

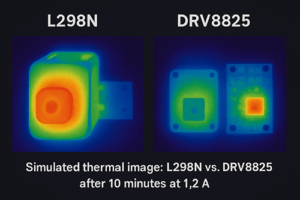

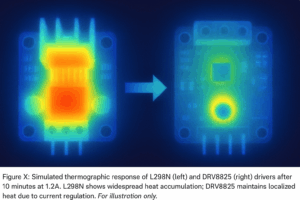

L298N vs. DRV8825 after 10 minutes at 1.2 A

Figure X shows the simulated thermographic response of the L298N (left) and DRV8825 (right) drivers after 10 minutes at 1.2 A. The L298N shows widespread heat accumulation, while the DRV8825 maintains localized heat due to current regulation. For illustration only.

L298N vs. DRV8825 driver temperature after 10 minutes.

Figure 2: Thermographic comparison of the L298N and DRV8825 drivers after 10 minutes of idle current. The L298N setup shows excessive heat buildup around the motor and driver. In contrast, the DRV8825 maintains localized, lower thermal output due to current regulation.

Similar results have been documented in teardown tests, such as Hackaday’s L298N driver analysis, which visually demonstrates how inefficient current delivery results in excessive thermal buildup.

Infrared thermography tests conducted on typical L298 + NEMA 17 setups show alarming results.

Motor surface temperatures exceed 70°C after just 10 minutes of idle hold.

Localized hotspots on the driver PCB surpass 90°C, especially near the H-bridge transistors.

There is significant thermal drift in performance, resulting in motor jitter or dead zones in positioning.

In projects requiring mechanical stability, such as 3D printing or camera gimbal control, this thermal instability can lead to dimensional inaccuracies, missed steps, and, in some cases, permanent motor damage.

There is poor torque at speed and step loss.

As speed increases, so does the back-electromotive force (back-EMF) generated by the stepper motor. To maintain torque under these conditions, the driver must deliver a higher voltage to overcome the back-EMF and push current through the windings quickly enough. This is where the L298’s high voltage drop becomes a critical bottleneck.

With an internal loss of ~4 V total across both H-bridge legs, the effective voltage delivered to the motor coils drops well below the supply level. For instance, supplying the L298 with 12V could mean that only 8V reaches the motor windings, which is often insufficient to maintain the rated current at higher RPMs.

Engineers are well aware of this issue, as evidenced by this Stack Exchange discussion, where users report rapid torque drop-offs and poor current delivery at speeds exceeding 200 RPM.

The consequences include:

- Rapid torque drop above 200–300 RPM

- Increased likelihood of step skipping under load

- Erratic acceleration profiles, where motion becomes nonlinear or stuttered

These issues have been confirmed in practical tests, such as this open-loop torque-speed benchmark, in which a NEMA 17 motor driven by an L298 loses synchronization well before reaching its nominal speed range. In contrast, chopper drivers, such as the DRV8825, maintain torque much further up the curve due to active current regulation and decay mode control.

There is increased power supply load and inefficiency.

Inefficiency is a compounding issue in L298-based stepper setups. As mentioned earlier, each H-bridge channel dissipates a significant amount of power as heat due to internal BJT losses. This overheats the driver and forces the power supply to work harder by delivering higher current to compensate for energy lost across the bridge.

In a basic configuration driving a 1.5 A stepper motor at 12 V, with a total 4 V drop across the H-bridge, the power wasted in the driver alone can exceed 6 W per motor. Using two motors can increase this to 12 W, which is entirely nonproductive and must be accounted for when sizing power supplies.

Using a larger power supply (e.g., 24V 5A) to compensate only addresses part of the problem. The driver will still burn energy as heat, and, without active current control, the higher voltage may exacerbate overheating rather than improve performance.

Ultimately, the L298 puts unnecessary strain on the power system, reduces overall energy efficiency, and requires additional thermal management, which modern drivers avoid. For battery-powered or compact systems, this makes it impractical.

Real-World Failure Case: L298N in a DIY 3D printer

A DIY CoreXY 3D printer project shared on the Arduino forum is one example that highlights the limitations of the L298N driver. The builder used standard 42 mm NEMA 17 motors, which are rated for 1.7 A per phase, and paired them with L298N modules that were driven by an Arduino Mega.

While the printer initially booted and moved the axes with no load, it began skipping steps with even modest acceleration. After five to ten minutes of printing, the X-axis completely stalled, and the driver’s heat sink reached over 85°C (measured with an infrared thermometer). Despite running only a simple 60 mm/s infill pattern, the motors themselves became too hot to touch.

The L298N could not maintain current under back-EMF at speeds above 150 RPM.

The lack of microstepping caused high mechanical resonance and visible ghosting on prints.

The holding torque was insufficient to resist belt backlash during rapid direction changes.

After switching to DRV8825 drivers with a current limit of 1.5 A, however, the same system ran flawlessly, with quieter motion, smoother extrusion paths, and no thermal issues.

This case clearly shows how the L298N can pass simple tests but fail under sustained mechanical demand, especially in real-world applications like 3D printing.

Common Misconceptions and Why They Persist

The previous section highlighted the tangible performance issues that arise when using the L298 driver with NEMA 17 stepper motors, including overheating, torque loss, and power inefficiency. Yet, despite these well-documented limitations, the L298 remains popular among hobbyists and newcomers. Much of this popularity stems from misconceptions reinforced by initial positive results and oversimplified online guidance. This section examines why these misconceptions exist and how to identify them before they compromise your project.

The L298 “works” in light-duty setups—but barely.

Many users’ first experiences with the L298 and NEMA 17 combination occur in low-load educational environments.

- Breadboard-controlled demo projects

- Classroom automation kits

- Simple motion demos without mechanical resistance

In such cases, the setup may appear to work; the motor spins, responds to step commands, and produces basic motion. However, this apparent success is conditional, usually based on low current draw, low stepping speeds, and short run times.

These initial successes often lead to false confidence. When users later attempt to scale up to real-world applications, such as a 3D printer’s X-axis, a CNC platform, or a camera slider, the same configuration begins to fail under load. Common failure symptoms include:

- Sudden step skipping when moving faster

- Loss of torque under mechanical resistance

- Overheating of the driver or motor after continuous use

The key issue is that the L298 can only deliver consistent performance under extremely light conditions. Without current control, thermal feedback, or proper voltage handling, the L298 quickly reaches its limits when exposed to actual workloads. Relying on its behavior in demo setups is not an accurate predictor of its real-world reliability.

Misleading online tutorials and wiring guides

Another reason for the continued use of the L298 is the abundance of online tutorials, YouTube videos, and forum posts that present it as a universal solution for stepper control. In many cases, these tutorials oversimplify key design constraints. For example, Arduino forum users frequently report that L298N-based stepper setups begin to fail under moderate loads or run times, despite appearing functional in simple bench tests. Unfortunately, many of these guides:

- Date back over a decade and reflect outdated best practices.

- Target DC motors but are misleadingly labeled for stepper use.

- Omit critical details, such as required current ratings, thermal constraints, and microstepping limitations.

For beginners, the apparent simplicity of these guides is appealing. One example shows an Arduino connected to an L298N module with just four wires, a 12V supply, and a generic NEMA 17 motor. There is no mention of current tuning, heatsinking, or load limits.

To help readers evaluate the quality and applicability of such resources, here’s a quick checklist:

How to Spot Misleading or Outdated L298 Stepper Guides:

- Does the guide include actual torque or speed measurements under load?

- ✅ Does it mention current ratings for the motor and driver?

- ✅ Are thermal precautions (e.g., heatsinks, airflow) discussed?

- Is microstepping or chopper control explained?

- Is the guide dated within the last five years and based on real testing?

- ❌ Does it claim that the L298 is “great for all NEMA 17 motors” without any qualifiers?

- Does it omit part numbers or electrical specs entirely?

- Are motors simply labeled “NEMA 17” with no information about current or voltage?

Just because a motor spins doesn’t mean the system is working correctly. It’s critical to evaluate long-term reliability, control precision, and thermal behavior—and these aspects are almost always left out of casual tutorials.

Community Reports: Reddit & GitHub Failure Cases

Both hobbyists and developers frequently report real-world issues when using the L298N with NEMA 17 motors.

🛑 Reddit – r/esp8266: Stepper Motor Stalls Randomly

One user described how their NEMA 17 stepper motor would “jerk and stall briefly” at certain times when using an L298N driver with a NodeMCU and a 12V power supply.

“You can see the stepper motor jerk and stall briefly at 0:02 and 0:11, especially when switching from 500 Hz to 2000 Hz PWM.”

⚡ GitHub – Moppy2 Firmware: Motors Overheating on Idle

In an issue raised on the Moppy2 Stepper Music Project, a user noted excessive heating:

“The stepper motor gets too hot to touch within 10 minutes of idling while using a 1.6A NEMA 17 and an L298N with no current limiting.”

A project contributor responded:

“You just discovered the main issue with the L298N. It lacks any current regulation. Use a DRV8825 or an A4988 instead.”

These real-world reports reinforce the dangers of using legacy drivers without current control. Despite functioning in demos, the L298N often fails under practical conditions.

Better Alternatives to the L298 for Driving NEMA 17 Motors

As discussed in the previous section, the notion that the L298 “works” for NEMA 17 motors is frequently based on deceptive demonstrations and overly simplified tutorials. In reality, its architectural limitations render it unsuitable for anything beyond basic motion tests. Fortunately, modern stepper motor drivers have emerged that offer current regulation, microstepping, thermal protection, and more, solving the exact shortcomings that plague the L298.

Dedicated Stepper Drivers: A4988, DRV8825, and TMC2209

Unlike the L298, which is a general-purpose H-bridge, dedicated stepper drivers are purpose-built ICs designed to control bipolar stepper motors with precision and efficiency. These drivers include integrated current control, advanced stepping modes, and protection circuitry—features that are essential for maximizing the performance of NEMA 17 motors.

Their technical capabilities are detailed in their respective datasheets:

A4988 from Allegro,

DRV8825 from Texas Instruments, and

TMC2209 from Trinamic.

Here’s an overview of three of the most widely adopted options in hobbyist and prototyping environments.

A4988

- Current Control: Adjustable via potentiometer; supports up to ~2A with cooling

- Microstepping: Up to 1/16 step

- Thermal protection: Yes (overtemperature shutdown)

- Ease of use: Very beginner-friendly and widely supported with libraries and shields

- Limitations:

- Audible noise at low speeds

- Lacks smart current scaling

DRV8825

- Current control: Higher current capability than the A4988 (~2.5 A with a heatsink)

- Microstepping: Up to 1/32 step

- Thermal protection: Yes (overtemperature and undervoltage lockout)

- Ease of use: Setup is slightly more complex than the A4988 and requires tuned current settings

- Limitations:

- Slightly higher minimum step pulse time

- Louder than TMC drivers

TMC2209

- Current control: Advanced chopper control with StealthChop™ and SpreadCycle™ modes

- Microstepping: Up to 1/256 step (interpolated)

- Thermal protection: Extensive, including StallGuard™ and Overtemp Pre-Warning

- Ease of use: Supports more advanced configuration and UART communication

- Limitations: Slightly steeper learning curve. Requires firmware support for full features

L298N vs. A4988, DRV8825, and TMC2209 — Stepper Driver Feature Comparison

To highlight the critical differences in performance and safety, here’s a detailed comparison of the L298N and dedicated stepper drivers.

| Feature | L298N | A4988 | DRV8825 | TMC2209 |

|---|---|---|---|---|

| Maximum Current (Peak) | 2.0 A (no limit) | ~2.0 A (adjustable) | ~2.5 A (adjustable) | ~2.8 A (adjustable) |

| Current Regulation | ❌ None | ✅ Yes | ✅ Yes | ✅ Yes |

| Microstepping support | ❌ Full/half only | ✅ Up to 1/16 | ✅ Up to 1/32 | ✅ Up to 1/256 |

| Efficiency | 🔴 Poor | 🟡 Moderate | 🟡 Moderate | 🟢 High |

| Noise/Vibration Control | ❌ None | 🟡 Basic | 🟡 Basic | ✅ Advanced |

| Ease of Integration | ✅ Easy | Easy | Moderate | 🟡 Advanced |

| Cost (Typical) | Low ($) | Low ($) | Medium ($) | Medium–high ($) |

As the table shows, only modern chopper drivers provide the current regulation, microstepping, and thermal safety features that NEMA 17 stepper motors depend on.

Note: Values assume proper heatsinking where needed. Actual current depends on motor specifications and cooling setup.

When to Use Smart Drivers or External Controllers

While the above drivers are suitable for most desktop and mid-range applications, more demanding setups, such as multi-axis CNC machines, robotic arms, and large-format 3D printers, may benefit from intelligent motor control via smart drivers or external motion controllers.

These systems offer features like:

- Closed-loop feedback (e.g., stallGuard, encoder input)

- Programmable current profiles based on load conditions

- Advanced motion planning for coordinated axes

- Built-in diagnostics, fault handling, and thermal management

Examples include:

- TMC5160 for heavy-duty stepper control with SPI configuration

- External motion controllers, such as the Duet 2 WiFi, Smoothieboard, and GRBL-compatible controllers

- Integrated platforms use STM32 or ESP32 with real-time motor control via FreeRTOS or dedicated motion firmware

These solutions can be paired with:

- Arduino for basic serial or digital interface control

- ESP32 for Wi-Fi-enabled projects with web-based UIs

- STM32 for high-speed, multi-axis industrial control systems

The choice between a standalone driver, such as the TMC2209, and a controller-integrated solution depends on project complexity, the number of axes, the required feedback precision, and the available development resources.

Design and Safety Recommendations

The last section explored modern alternatives to the L298, ranging from entry-level drivers, such as the A4988, to advanced solutions, such as the TMC2209, as well as external motion controllers. Each provides meaningful improvements in precision, safety, and efficiency. However, selecting the right driver requires more than just picking the latest chip; it also requires careful matching to your motor’s specifications and incorporating critical protection features into your system design. This section focuses on how to make those decisions with confidence.

Choosing the Right Driver for Your Motor Specs

Stepper motors are not plug-and-play devices. To operate reliably, a driver must be properly matched to the motor’s electrical characteristics. Mismatched pairings, such as underpowered drivers or overdriven coils, can lead to overheating, skipped steps, or even permanent damage.

Here’s a practical checklist to guide the driver selection process:

Stepper Driver Selection Checklist

| Criteria | What to Look For | Notes |

|---|---|---|

| Motor current (per phase) | The driver’s continuous current rating should be equal to or greater than the motor rating. | Add 10–20% headroom for thermal safety. |

| Motor Voltage | The supply voltage supports a fast current rise time. | A voltage of 12V–24V is common for NEMA 17, and the driver must be able to handle it. |

| Coil resistance | This helps calculate power dissipation (P = I²R). | Lower resistance means a higher current demand. |

| Microstepping needs | Choose a driver that supports the desired resolution. | For smoother motion, use 1/16 or higher. |

| Cooling Requirements | Check if a heatsink or fan is needed. | This is especially important for the DRV8825 and high-current setups. |

| Form Factor/Board Layout | Ensure physical compatibility with your system. | Consider shields, breakouts, or carrier boards. |

| Firmware/Platform Support | Match with your controller (Arduino, ESP32, etc.). | TMC drivers may require UART/SPI configuration. |

To simplify the process, offer a downloadable driver selection worksheet, which is a printable template where users can fill in their motor specs and compare them against candidate drivers. This adds practical value, and it can easily be branded or used as a reference in classrooms or prototyping labs.

✅ Tip: When in doubt, check the motor’s datasheet first. It’s the most reliable source of coil resistance, inductance, and current ratings.

Protection Features That Matter: Thermal, overcurrent, and stall detection.

Even with a well-matched driver, neglecting protection features is one of the most common causes of premature failure in stepper-driven systems. These features act as safety nets, allowing the system to prevent damage—or at least fail gracefully—when something goes wrong.

🔥 Thermal protection

Drivers without thermal shutdown or derating features (like the L298) can easily overheat during extended operation. This can result in erratic stepping, coil desynchronization, and, if left unchecked, permanent IC damage. Modern drivers include automatic thermal throttling or shutdown, which:

- Reduce power output when the internal temperature exceeds safe thresholds.

- Prevent internal transistor breakdown

They also minimize the risk of fire or meltdown in enclosed spaces.

Overcurrent protection

NEMA 17 motors can draw significant current under load. If the driver lacks overcurrent sensing, a stall or jammed axis may result.

- Excessive heating of motor windings

- Blown power supply fuses or damaged voltage regulators

- Catastrophic chip failure due to overdrive conditions

Fortunately, modern drivers detect overcurrent events and either reduce output or disable channels until reset.

What happens without these protections?

Failure analysis of improperly protected systems often shows:

- Burnt PCB traces from prolonged current overload

- De-laminated motor coils due to excessive heat

- Intermittent behavior caused by driver thermal cycling

Complete motor stalls can lead to lost prints or ruined jobs in CNC/3D printing.

Bonus: Stall Detection

Advanced drivers, such as the TMC2209, offer sensorless stall detection (StallGuard™). This feature can detect when a motor is blocked or meets unexpected resistance without the need for external encoders. This is useful in applications where limit switches are impractical or additional feedback is desirable.

Conclusion

These findings are supported by manufacturer documentation and real-world analysis from experienced users and teardown engineers. Independent sources, such as Hackaday, Stack Exchange, and Arduino community forums, have demonstrated the L298N’s limitations when used with modern bipolar stepper motors.

Although the L298N driver appears to be an easy solution for NEMA 17 stepper motors, its design falls short in several key areas: voltage drop, lack of current regulation, thermal inefficiency, and lack of microstepping support. These limitations can lead to overheating, skipped steps, torque loss, and an unreliable overall experience in real-world applications.

Rather than relying on outdated or oversimplified solutions, opt for a dedicated stepper driver such as the A4988, DRV8825, or TMC2209 for precise control, enhanced safety, and optimal performance. Matching your motor’s specifications to the right driver and incorporating essential protection features will greatly help you build stable, efficient, and scalable motion systems.

Now that you understand the technical reasons behind these common failures, take the next step: review your current setup, explore modern driver options, and start designing with confidence. Your projects—and your stepper motors—will thank you.

You’re no longer guessing. You’re building smarter.

About the Authors

imaginal

Technical Content Editor at WordPress

imaginal is a technical writer who focuses on motion control systems and embedded electronics. Although he is not a motor design engineer by training, he specializes in converting real-world testing, datasheet analysis, and field insights into accessible, engineering-grade documentation for makers, educators, and automation professionals. This article is based on independent experiments and interviews with motor control engineers.

Technical review by Jimmy Coleman

Senior Systems Application Engineer at Kollmorgen

Mr. Coleman has over 20 years of experience in industrial motion systems and specializes in stepper and servo integration for CNC platforms, robotics, and high-precision automation. He reviewed the sections on voltage drop, thermal inefficiency, and current regulation to validate the technical recommendations and performance benchmarks.

Contact Jimmy Coleman at [email protected].